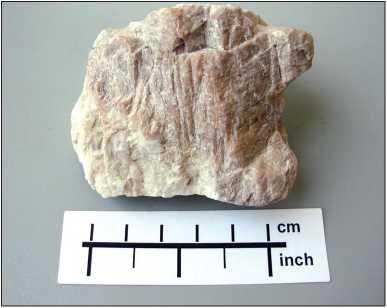

Separation of Quartz & Feldspar

|

1. |

Title of Product/Design/Equipment |

Separation of Quartz & Feldspar |

|

|

2. |

IPR Status Patent/Abroad IPR Details |

- |

|

|

3. |

Application/Uses |

||

|

4. |

Salient Technical Features including Competing Features |

The process is based on recovery of minerals by froth flotation.The separation of quartz and feldspar from the ground ore-slurry is achieved by differential flotation using a suitable reagent scheme. |

|

|

5. |

Level/Scale of Development |

10 kg-scale. Further scale-up is possible. |

|

|

6. |

Environmental Considerations |

Installation of tailings and effluent disposal systems is needed |

|

|

7. |

Status of Commercialization |

Ready for commercialization |

|

|

8. |

Major Raw Materials to be Utilized |

Ore/ Mica mine waste dump containing quartz and feldspar, flotation reagents |

|

|

9. |

Major Plant Equipment and Machinery Required |

Crusher, Grinding Mill, Classifier, Conditioner, Flotation cells, Dewatering Units |

|

|

10. |

Techno-Economics |

Available on demand. Chemical requirement cost is about Rs. against product cost of about Rs. per ton of iron oxide production. |

|

|

11. |

Technology Package |

(a) Process knowhow, (b) Details of equipment & (c) Quality assurance methods. Assistance in setting up the plant on |

|

Chemical requirement cost is about Rs. 30.7 against product cost of about Rs. 1.25.7 per ton of iron oxide production.